GRQ Clamps

GRQ Standard Clamps

|

TC Fittings, TC Clamp, Universal / All Standards, GRQ |

|||||||

|

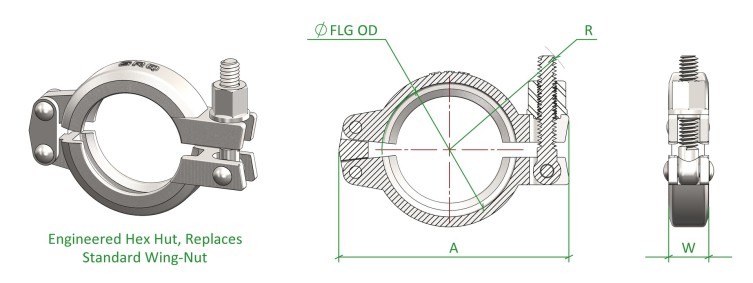

Size |

FLG OD |

A |

W |

R |

Max Operating Pressure @ 150°C (bar) |

TUV Max Test Pressure @ 150°C (bar) |

Part Code |

|

0.50"-0.75" |

25.40 |

73 |

16 |

67 |

50 |

100 |

CC.GRQ.0050-0075.4 |

|

DN10/15/20 |

34.00 |

84 |

16 |

71 |

50 |

100 |

CC.GRQ.D010-D020.4 |

|

1.00"-1.50" |

50.50 |

104 |

16 |

80 |

50 |

100 |

CC.GRQ.0100-0150.4 |

|

2.00" |

64.00 |

118 |

16 |

85 |

50 |

100 |

CC.GRQ.0200.4 |

|

2.50" |

77.50 |

131 |

16 |

90 |

50 |

100 |

CC.GRQ.0250.4 |

|

3.00" |

91.00 |

145 |

16 |

96 |

40 |

80 |

CC.GRQ.0300.4 |

|

3.50" |

106.00 |

160 |

16 |

102 |

30 |

60 |

CC.GRQ.0350.4 |

|

4.00" |

119.00 |

173 |

16 |

108 |

25 |

50 |

CC.GRQ.0400.4 |

|

4.50" |

130.00 |

184 |

16 |

112 |

25 |

50 |

CC.GRQ.0450.4 |

|

5.00" |

144.40 |

203 |

17 |

122 |

25 |

50 |

CC.GRQ.0500.4 |

|

5.50" |

155.00 |

216 |

23 |

133 |

25 |

50 |

CC.GRQ.0550.4 |

|

6.00" |

167.00 |

230 |

23 |

138 |

20 |

40 |

CC.GRQ.0600.4 |

|

6.58" |

183.00 |

244 |

23 |

145 |

20 |

40 |

CC.GRQ.0658.4 |

|

8.00" |

217.40 |

279 |

23 |

161 |

15 |

30 |

CC.GRQ.0800.4 |

|

8.58" |

233.50 |

303 |

23 |

168 |

15 |

30 |

CC.GRQ.0858.4 |

|

10.00" |

268.00 |

330 |

24 |

185 |

12 |

25 |

CC.GRQ.1000.4 |

|

10.75" |

286.10 |

349 |

24 |

194 |

12 |

25 |

CC.GRQ.1075.4 |

|

12.00" |

319.00 |

382 |

24 |

210 |

10 |

20 |

CC.GRQ.1200.4 |

|

12.75" |

338.00 |

402 |

24 |

220 |

9 |

18 |

CC.GRQ.1275.4 |

GRQX Clamps (With Hex Nuts)

Ideal for applications where operator safety is required, ensuring a spanner or socket is required to open potentially hazardous process lines.

|

TC Fittings, TC Clamp, Universal / All Standards, GRQX (With Hex Nut) |

|||||||

|

Size |

FLG OD |

A |

W |

R |

Max Operating Pressure @ 150°C (bar) |

TUV Max Test Pressure @ 150°C (bar) |

Part Code |

|

0.50"-0.75" |

25.40 |

62 |

16 |

48 |

50 |

100 |

CC.GRQX.0050-0750.4 |

|

DN10/15/20 |

34.00 |

73 |

16 |

52 |

50 |

100 |

CC.GRQX.D010-D020.4 |

|

1.00"-1.50" |

50.50 |

93 |

16 |

57 |

50 |

100 |

CC.GRQX.0100-0150.4 |

|

2.00" |

64.00 |

107 |

16 |

62 |

50 |

100 |

CC.GRQX.0200.4 |

|

2.50" |

77.50 |

120 |

16 |

68 |

50 |

100 |

CC.GRQX.0250.4 |

|

3.00" |

91.00 |

134 |

16 |

73 |

40 |

80 |

CC.GRQX.0300.4 |

|

3.50" |

106.00 |

149 |

16 |

80 |

30 |

60 |

CC.GRQX.0350.4 |

|

4.00" |

119.00 |

162 |

16 |

86 |

25 |

50 |

CC.GRQX.0400.4 |

|

4.50" |

130.00 |

173 |

16 |

91 |

25 |

50 |

CC.GRQX.0450.4 |

|

5.00" |

144.40 |

192 |

17 |

101 |

25 |

50 |

CC.GRQX.0500.4 |

|

5.50" |

155.00 |

205 |

23 |

107 |

25 |

50 |

CC.GRQX.0550.4 |

|

6.00" |

167.00 |

219 |

23 |

113 |

20 |

40 |

CC.GRQX.0600.4 |

|

6.58" |

183.00 |

233 |

23 |

120 |

20 |

40 |

CC.GRQX.0658.4 |

|

8.00" |

217.40 |

268 |

23 |

137 |

15 |

30 |

CC.GRQX.0800.4 |

|

8.58" |

233.50 |

292 |

23 |

144 |

15 |

30 |

CC.GRQX.0858.4 |

|

10.00" |

268.00 |

319 |

24 |

162 |

12 |

25 |

CC.GRQX.1000.4 |

|

10.75" |

286.10 |

338 |

24 |

171 |

12 |

25 |

CC.GRQX.1075.4 |

|

12.00" |

319.00 |

371 |

24 |

188 |

10 |

20 |

CC.GRQX.1200.4 |

|

12.75" |

338.00 |

391 |

24 |

198 |

9 |

18 |

CC.GRQX.1275.4 |

GRQClampPressureTesting.pdf

Adobe Acrobat document [863.6 KB]

Why Choose GRQ Clamps?

Designed by our engineers to meet the service requirements of our customers and end users. Easily seen advantages of the GRQ clamp:

- TUV Pressure tested and certified.

- Patented in Europe & USA.

- Unique patented sealing profile guarantees optimum leakproof assembly without overtightening.

- Superior design at a competitive cost.

- Alleviates problems associated with known clamps.

GRQ Wing Nuts

The GRQ Wing Nuts have an ergonomic taper which is wider at the top of the nut. The tapered feature helps keep the operatorʼs hand from slipping off the nut when tightening. The arm of the clamp is recessed so that the contact ring of the nut seats consistently into a pocket. This improves the accuracy and the consistency of the clamping pressure. The seat and nut also help prevent the clamp from swinging open if it should loosen in service.

GRQ Double Pin Cast Hinge

The GRQ clamps utilize an investment cast hinge and two pivot point pins per clamp to vastly improve the strength and uniformity of the clamping pressure as compared to single pin designs. Single pin designs pivot at one point creating uneven load on the connection which effects gasket intrusion and performance. The double pin design allows the clamp to float into place, compensating for misaligned piping and position the pipes into proper alignment.

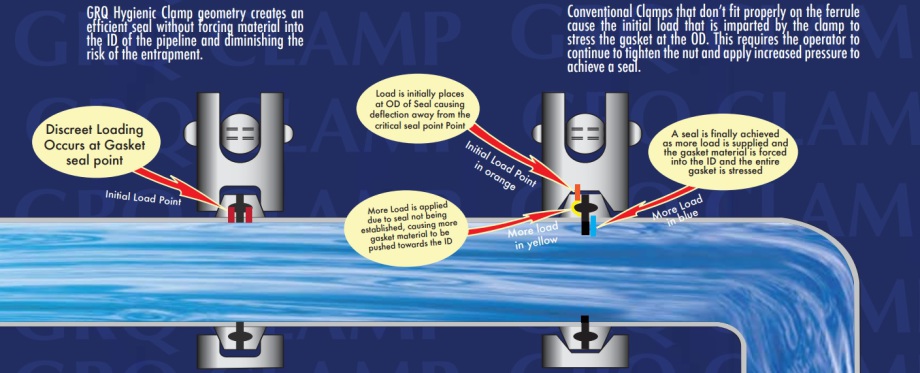

Sealing 101 and the hygienic clamp connection.........

Flowsource Process Fittings is the first company in the industry to take an engineered approach to address the entire clamp connection. Itʼs important to understand the principle of both sealing and the design of the connection before you can understand our comprehensive approach to correct the problem.

The principles of sealing

To establish a seal, the pressure at the seal point has to be greater than the pressure of the process flow. Therefore if the pressure in the line is 40 psi for example, then the pressure on the ferrule face to the gasket face must be greater than 40 psi to achieve a seal. The sealing pressure that is required must be imparted to the entire area of the seal point. To accomplish this you must have the correct geometry to achieve a discreet sealing point. Flowsource Process Fittings has created a clamp assembly that places the clamp load directly onto the face of the seal point. We have also designed our gaskets to direct the load onto the seal point as well by tapering the gaskets and making the ID larger so that the gasket compresses to the ID and not beyond.

What is the sealing point of a hygienic gasket?

The seal point of any hygienic clamp gasket is the corner of the ID at the gasket face. The o-ring bead is often confused as the seal point with a clamp gasket but is actually a locator. If fluid reaches the o-ring bead, the critical seal point has already been breached and bacteria growth can occur. FlowSmartʼs clamps and gaskets are designed to put the loading on the ID of the gasket.

GRQ Clamps -vs- Conventional Clamps